IMPARTIAL AND INDEPENDENT PERIODICAL INSPECTION AND VERIFICATION SERVICE

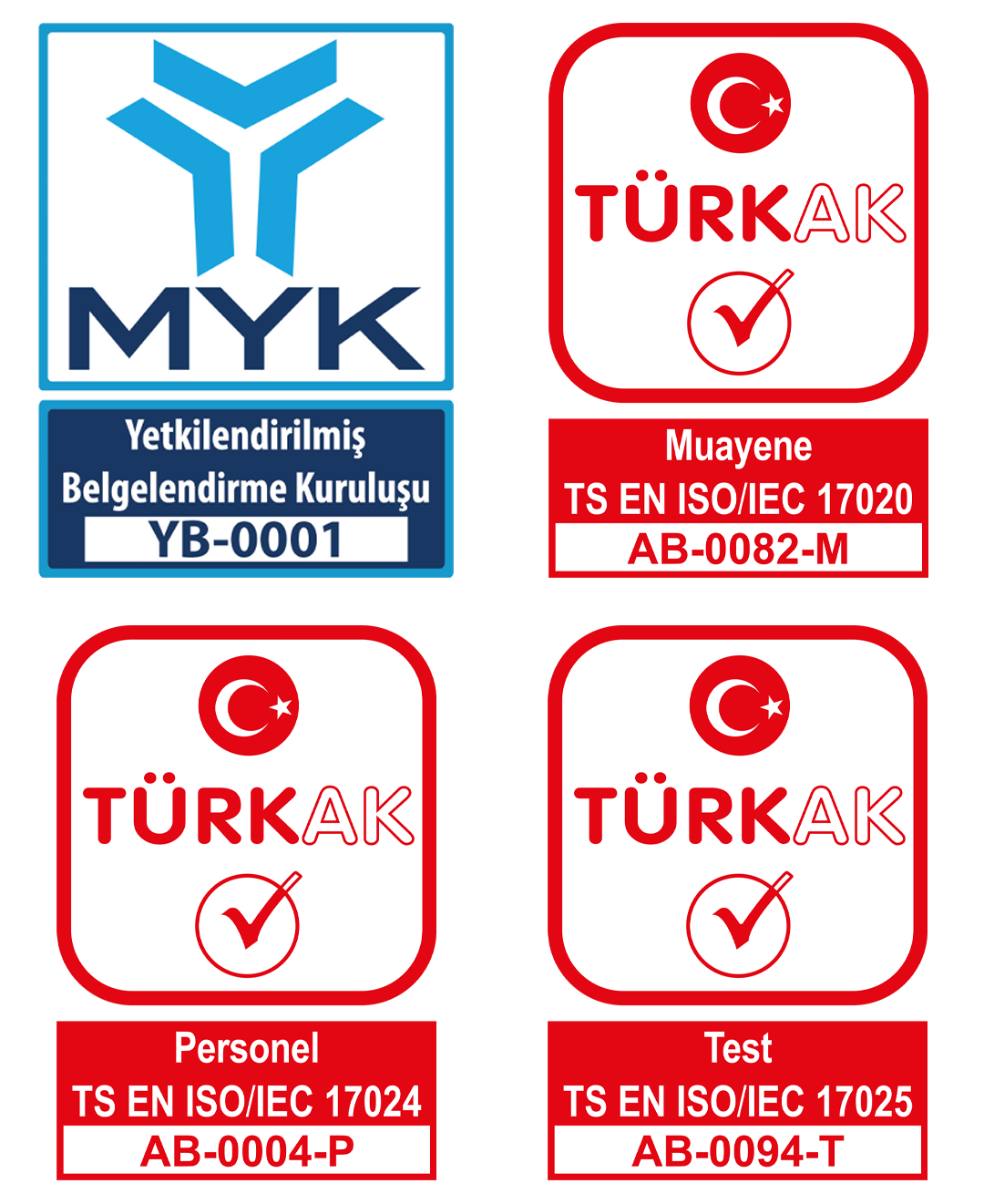

For more than 15 years, we have been providing periodical inspection and verification service impartially and independently in calibration and inspection activities with our specialist personnel in their fields and our facilities, and, for natural gas meters and calorimeter fields, under the accreditation of Turkish Accreditation Agency (TURKAK).

Our high quality services in this field contributes significantly in formation of the high quality and sustainable infrastructures, while paving the way for development of local and national production possibilities for our country. Also, we are aiming at recovering the meters which undergo periodical inspections and verifications, accordingly supporting our national capital.

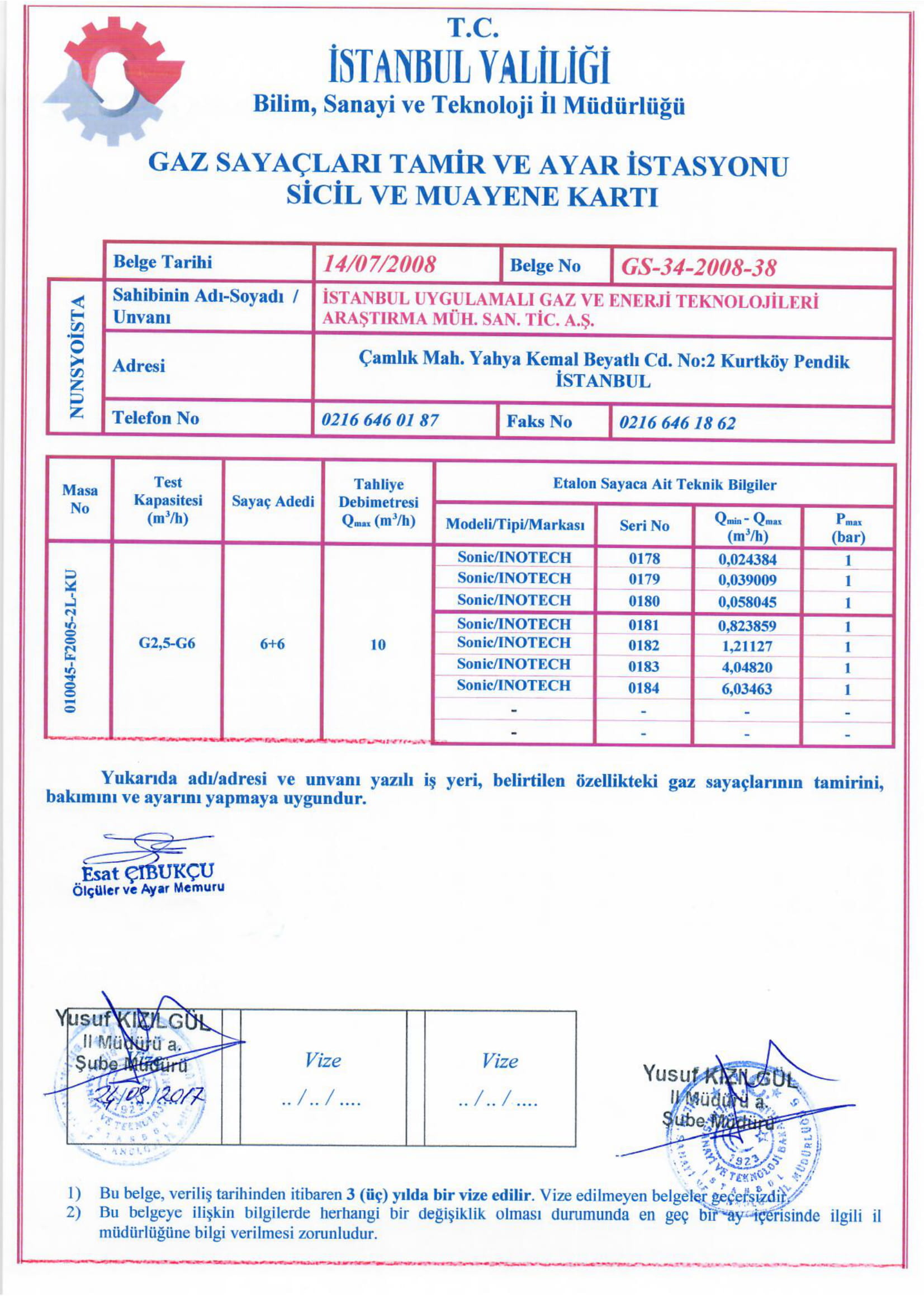

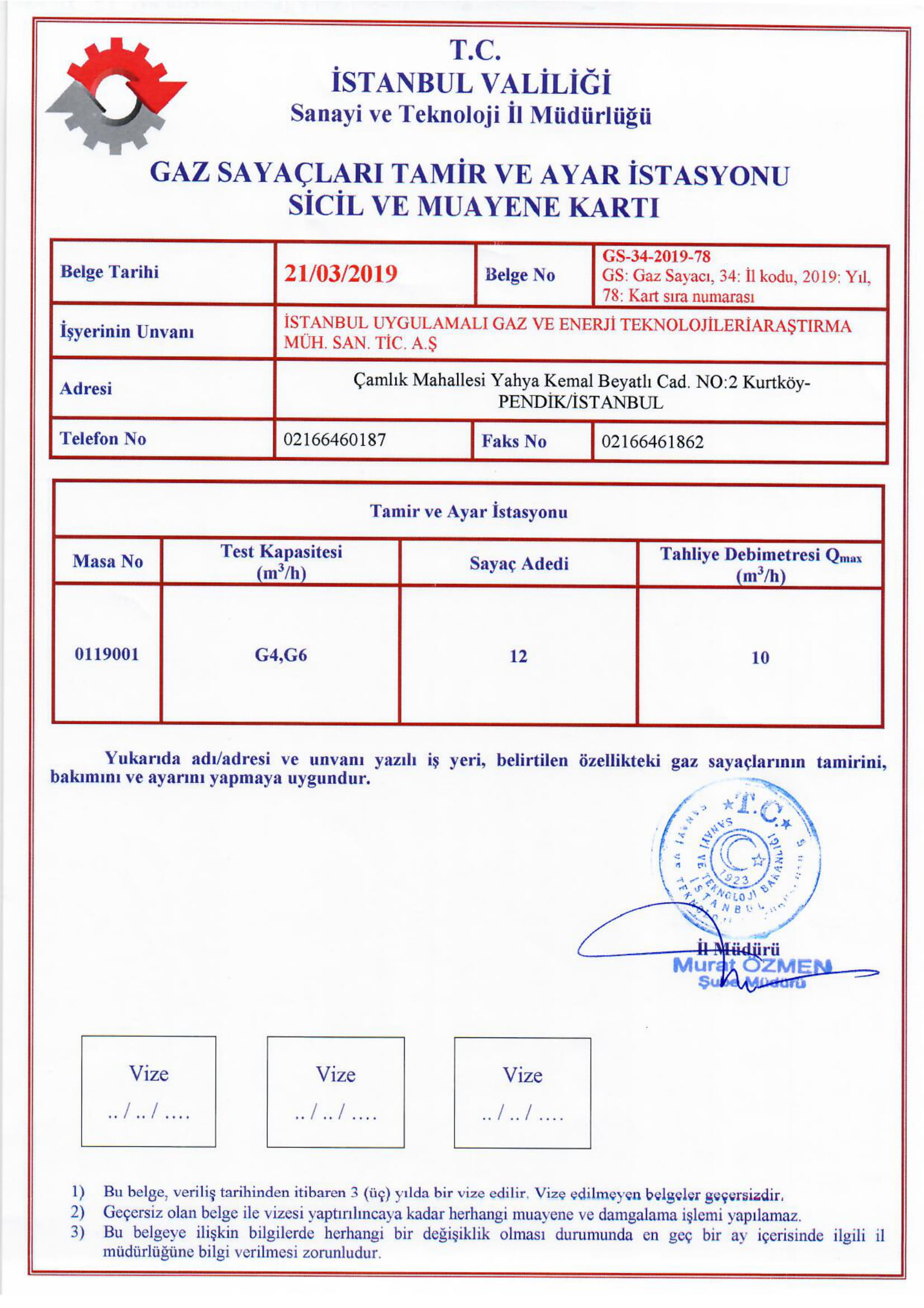

We, as UGETAM, have been successfully carrying out meter dismantling and installation works with our specialist teams since 2008. In this period, we completed dismantling and installation and periodical inspection process of approx. 4,000,000 meters. While doing these operations, we have not caused any interruption in gas supply enjoyed by subscriber.

We conduct these tests in order to check operation of meters at desired values on the basis of the reference values prescribed in the applicable standards.

Why Calibration is Important?

Metering value from a device not verified is merely an assumption. Because metering with a non-calibrated device entails disagreements in conflict with the rationale of metering.

If we are to provide an example, you are seeing consumption values changing every day on the water, natural gas meters located in front of your doors. The question of “Did I actually consume those values?" will only be answered by the verification tests.

When and How Meter Calibration Done?

According to the applicable provisions of Measurement and Measuring Instruments; periodical inspections and verification must be performed;

– every 10 years, for gas and water meters

– every 5 years, for calorimeters

Meters will be stored for a minimum of 4 hours under the required temperature conditions at the test laboratories to ensure thermal equilibrium. Meters so conditioned are connected to test station. Data from meter are entered in the software of test station, and then recording starts. After identifying the operating range of the meters according to relevant test standards, types and diameters, testing process starts. According to the results of the test, acceptance report for the meters which are within operating range are issued, otherwise, a reject report will be issued.

Why UGETAM Calibration Laboratory?

Enjoying the status of being the most extensive laboratory of Turkey, our UGETAM Gas Meter Test and Inspection Laboratory works at full capacity. We carry out high-precision tests of all domestic, commercial and industrial type diaphragm, rotary, turbine and ultrasonic meters of any brand used in natural gas distribution.

We carry out repair and maintenance of the meters when the metering error margins go beyond the necessary limits. We measure metering error values at all signal points of a meter, and handle entire calibration process in a computer controlled environment independently of the operator.

WHAT TYPES OF CALIBRATIONS WE CARRY OUT?

NATURAL GAS METER TESTS

- Accuracy (Metering Error) Tests

- Pressure Loss Test

- Periodical Inspection

- Metrologic Repeatability Test

CALORIMETER TESTS

- Pressure Loss Test

- Performance Test

- Periodical Inspection

- Inspection Upon Complaint

- Inventory Inspection

- Accuracy Inspection

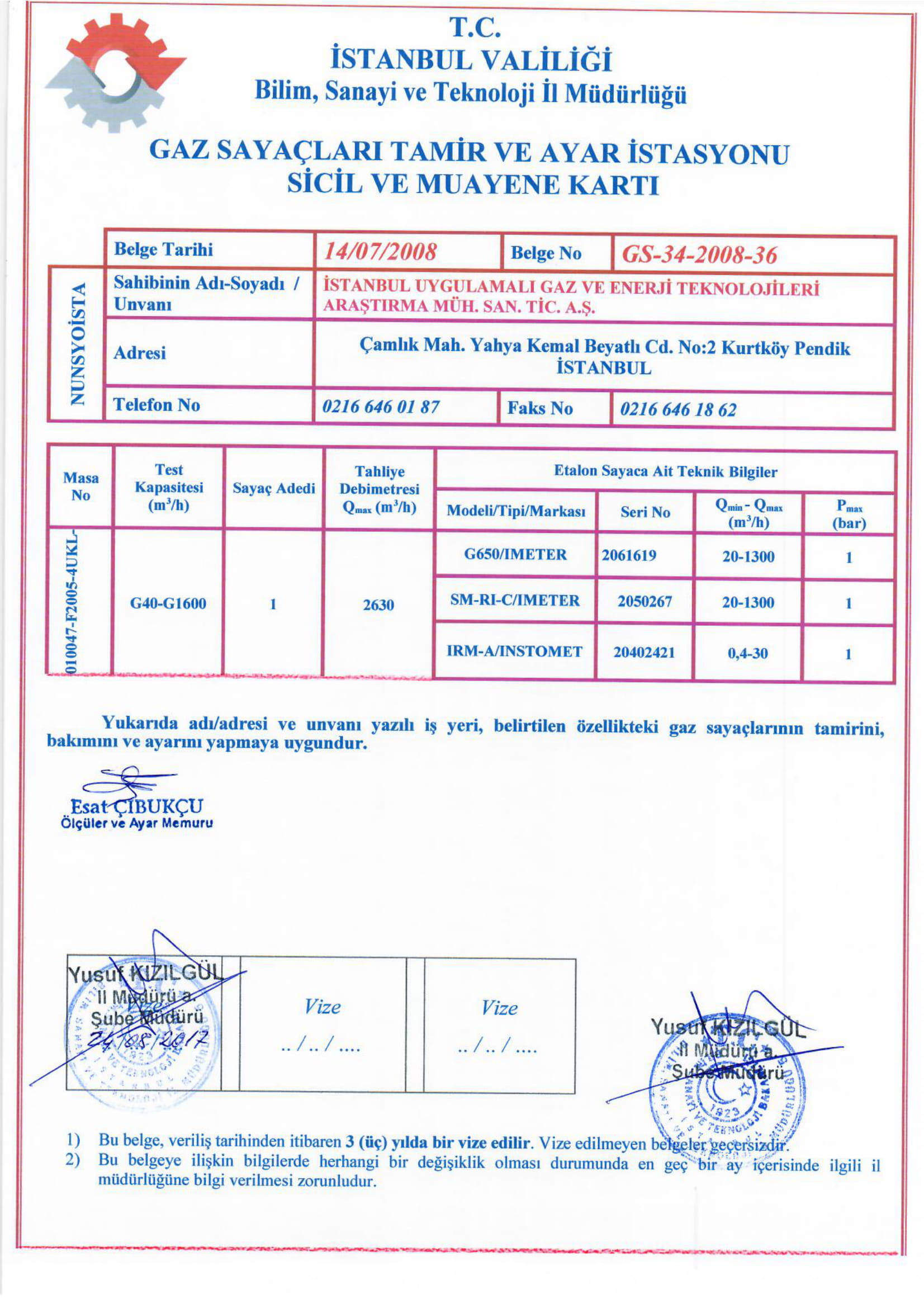

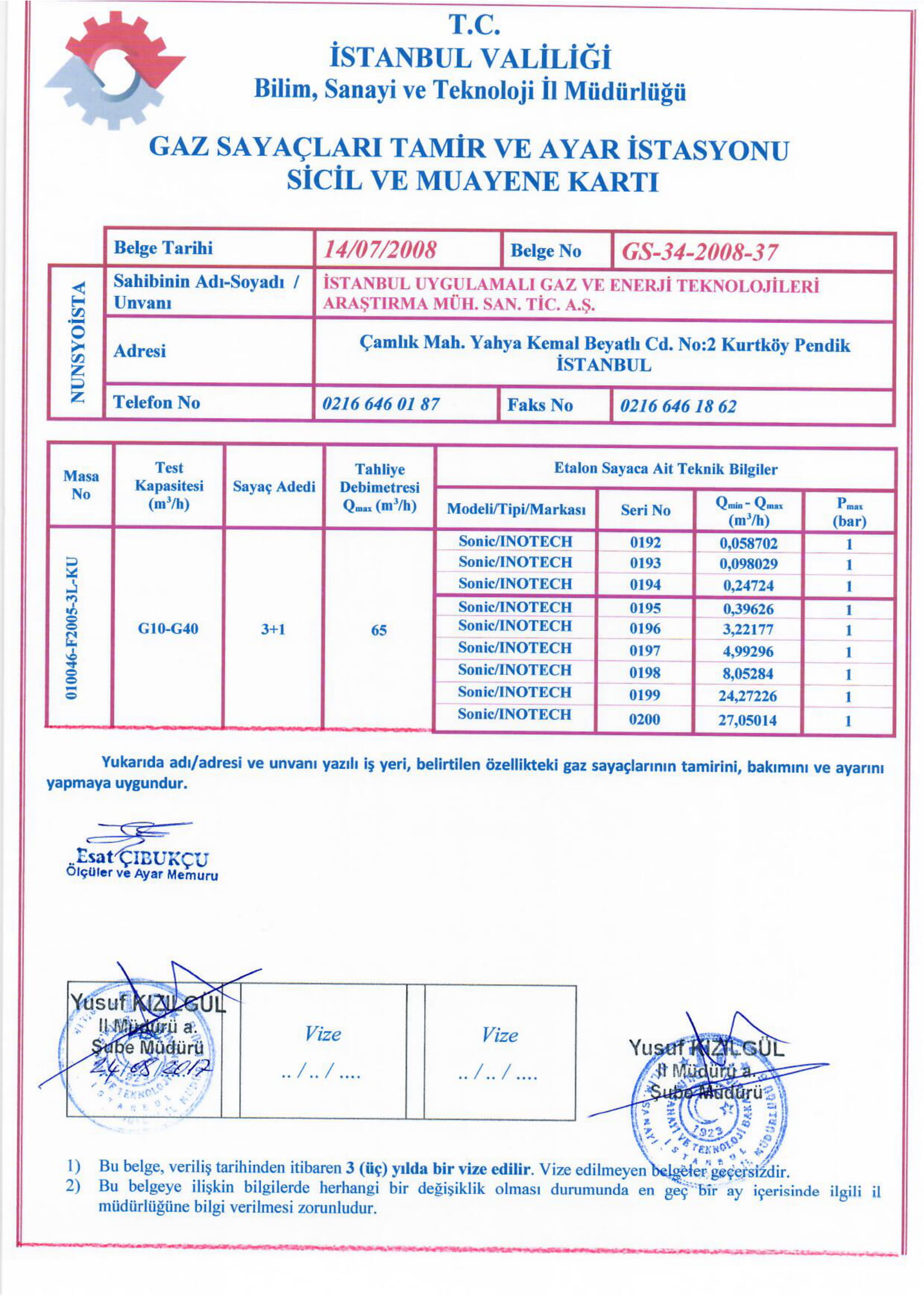

OUR AWARDS AND CERTIFICATES OF ACHIEVEMENTS